Learning Turning

Here is a short bio of my learning to turn.

I started turning after taking a turning class at Maryland Hall taught by Joe Dickey back in 1996. I would recommend that anyone that is interested in turning to contact the Maryland Hall and sign up for one of the classes that are taught there by members of the Chesapeake Wood Turners club. The Maryland Hall has an excellent wood turning Coop that allows access to lathes by anyone without a lathe at home to have fun turning. My first lathe was a Rockwell which I used until 2010 when I bought a Powermatic. I also have a small Grizzly lathe that I use to turn pens and other small objects on. Why two lathes, that is what my wife keeps asking me, well cause I can.

Here is a picture of the first bowl that I turned in that class.

It was turned wet and when it dried (via microwave) it warped into an oval. I barely had enough wall left to complete the rim. Beginners luck, I had just enough. While I was taking the course I did not have a lathe at home. I bought one just after I finished the class. I was torn between getting a small lathe or a midsized/large one. After asking the instructors I was told; on a small lathe you can do small things, on a big lathe you can to big AND small things. Therefore I bought in November 1996 a large Rockwell/Delta 46-201 lathe like the one shown below.

A picture of my first lathe.

Moving on, I started to obtain accessories for the lathe, gouges, scrapers, the dreaded skew, and chucks. The lathe is similar to a router, they can give you the router/lathe and then you have to get the bits and gouges to make them useful.

Before I continue my saga there are two SAFETY RULES that I always observe when using my lathes.

- ALWAYS WEAR A FULL FACE SHIELD Safety glasses are not sufficient.

- NEVER USE CLOTH RAGS AROUND THE LATHE

After getting “critical mass” of accessories, I proceeded to turn bowls, most were utilitarian bowls of around 8 to 12 inches in diameter and 4 to 6 inches deep. Unfortunately I gave away these early bowls without taking pictures of them. I do recall that most of them were box elder wood with boiled linseed oil finish. My career got in the way of much turning from 1997 on. I did turn an occasional bowl and pen but no serious turning.

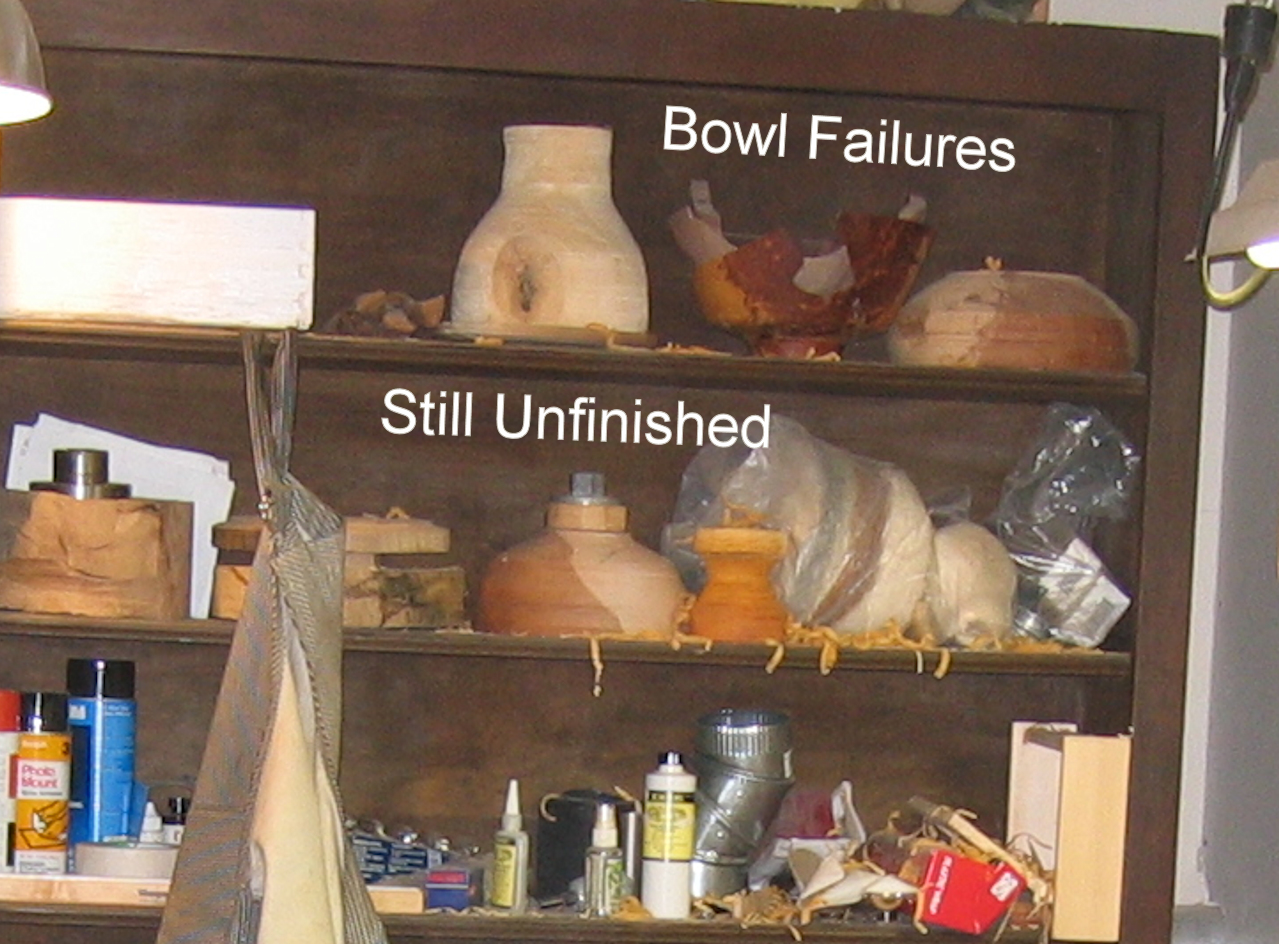

My wife does not want me to show you my less than stellar moments, but as with anything that you do, practice makes perfect. My most memorable OOPs experience was turning a large black walnut bowl this was going to be 12” diameter and 8” deep. It is not easy to find a bowl blank that is that size, I was turning the inside of the bowl and was not paying attention to the wall thickness were it transitioned to the bottom. BANG, in an instant the bowl broke into 5 or 6 pieces and went flying across my workshop. (Hence the warning about full face shield) I never did find all the pieces. What I ended up with was a 6” diameter saucer that was 1 ½” deep. I kept the parts that I could find and put them on a shelf to remind myself to pay closer attention to transition points. Here is the shelf with the bowl pieces.

There are actually two failures shown. The ones marked "Still Unfinished" are indeed, to this day in 2020, still not finished.

The point I am trying to make is to not get discouraged when things don’t go as planned. I have other OOPs like the times (yes more than once) I went too deep and ended up making what we call a funnel.

What you see in the center of the bowl is the waste block that gets removed when the turning is finished.

I have finally achieved a level of experience that most of my standard bowl making goes without incident, but you will always find that one piece of wood that will just fly apart without you making a mistake. That is not to say that I have not had trouble while expanding my talents (always wear a full face shield). I can truthfully say that I have a lot of fun at the lathe. How do you tell a happy turner? It is when he is standing in front of his lathe with 6 or more inches of shavings under his feet.

The shavings on the floor were made producing these.

Since 1996 I have been a member of the Chesapeake Wood Turners club that meets on the third Saturday of each month (except July) at the Maryland Hall in Annapolis. I am also a member of the American Association of Woodturners. The AAW has many turning tutorials on their website that can be accessed by clicking here.

I currently turn and augment with my laser engraver:

- Bowls

- Pens

- Tap Handles

- Spin Tops

- Lidded Boxes

- Wine Stoppers

- Penn State Industries has many unique items for the turner that I have made.

I hope this has not been too boring.

Lou Prugh